汽车用预浸基板材料的实现方案

DIC公司宣布,其与福井赛伦和福井县工业技术中心合作的项目已被新能源和工业技术发展组织(NEDO)选为2018年财政年度节能技术战略创新方案(商业发展阶段)的主要研究项目。

原文如下:

DIC Corporation announces that its project in collaboration with Fukui-based Seiren and the Industrial Technology Center of Fukui Prefecture has been chosen as a major research project by the New Energy and Industrial Technology Development Organization (NEDO) for its fiscal year 2018 Strategic Innovation Program for Energy Conservation Technologies (commercial development phase).

The project focuses on the commercialization of fast-curing prepreg made with carbon fiber composites for automotive applications.

The NEDO program seeks to advance the development of technologies that will contribute to create an energy-efficient economy and society and/or improve the competitiveness of Japanese industry. The program selecs and subsidizes technological development project with the potential to reduce energy consumption. (Projects selected in fiscal year 2018 will be subsidized from fiscal year 2018 through fiscal year 2020.)

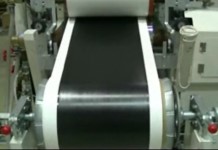

The project brings individual technologies by three specialists together; DIC’s radical-curing resin (cures in less than one minute at 150°C) that leverages its original polymer design technologies; the Industrial Technology Center of Fukui Prefecture’s tow spreading (processes fiber bundles into flat sheets) and high-speed prepreg processing technologies; and Seiren’s high-quality prepreg processing and quality management technologies. The goal is to develop fast-curing prepreg suitable for mass production that achieves both low production costs and high quality within the world’s shortest production time. The prepreg can also be stored at room temperature.

The project also includes the development of a high-speed manufacturing mass production process for commercialization and mass production of the new prepreg, which reduces the energy consumption required for production and molding and improves vehicle fuel economy by reducing vehicle weight. As a result, the project is expected to yield a 90,000 kl (crude oil equivalent) reduction in energy consumption in 2030.

In recent years, automakers have focused on reducing vehicle weight with the aim of boosting fuel economy. While this trend has driven a steady increase in the use of carbon fiber composite materials in vehicle challenges remain such as the final cost arising from expensive materials and slow molding speeds. DIC, the Industrial Technology Center of Fukui Prefecture and Seiren continue working together to achieve mass production of their new prepreg with the aim of overcoming this challenge and encouraging adoption by automakers. In doing so, the three organizations look forward to realizing a product that helps in further advance the popularity of carbon composite materials.