Cevotec通过多材料铺设扩大了夹层结构的应用范围

光纤贴片放置(FPP)已成为复杂纤维复合材料部件自动化生产的选技术。具有适当尺寸的贴片的部件的增材制造尤其用于航空航天和汽车工业,医疗设备和运动设备。通过与的航空航天工业零部件制造商的密切合作,Cevotec根据行业要求进一步开发整个贴片贴装工艺。

Cevotec的FPP专家对复杂的夹层部件及其复杂的材料混合物特别感兴趣,如粘合膜,玻璃纤维和碳纤维层。这些不同的材料用于改善碳纤维材料与常用的铝蜂窝夹层芯的粘合性和可加工性。

“我们目前正在开发的SAMBA Multi生产系统能够在一个系统中自动铺设这种特殊的多材料混合物,”Cevotec席技术官Felix Michl表示。

除了玻璃纤维羊毛,金属结构和木芯,蜂窝芯,固体泡沫和其他材料已经享受了负载调整的纤维补片增强。根据工艺要求,可以在线生产或与生产线并行完成,以优化循环时间。

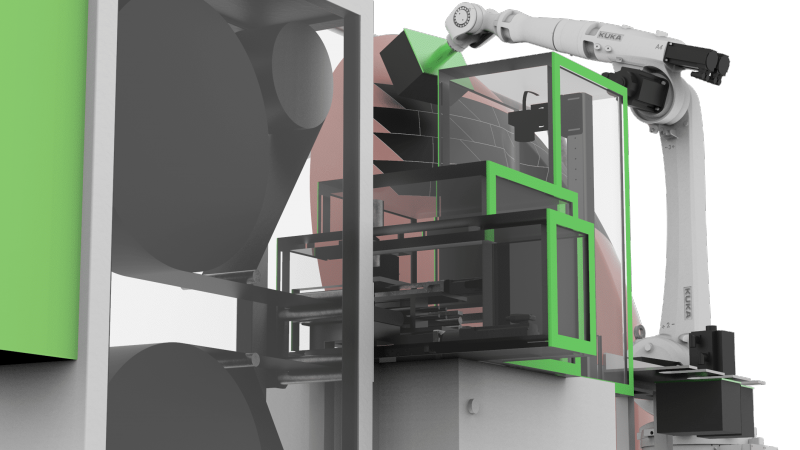

SAMBA Multi具有用于不同材料的平行进料装置,这些装置在一个生产系统中加工并精确放置在三明治芯或预成型工具上。通过将FPP单元安装在线性轴上,该概念还使得能够在航空航天应用中生产特别长且宽的部件。根据特定的元件尺寸,我们还根据DIN-A5和DIN-A4尺寸调整贴片夹具,以满足普通飞机部件的要求。集成的夹持站可在此过程中更换夹具。

“复杂夹层部件的自动化多层材料铺设对加工时间和生产量产生了极为积极的影响,”Cevotec董事总经理Thorsten Groene解释道:“压力和热量受控的纤维沉积能够避免中间压实因此,Groene继续说道,FPP可持续地降低许多应用中的经常性生产成本。当然,材料节省20% - 50%起着重要作用,但FPP自动化通常可以进一步优化整个过程。“

SAMBA Multi的另一个优点是生产过程的高可扩展性。“同一个过程每年都会产生几百到几千个单位,”Michl解释道。例如,这些是即将到来的“飞行汽车”行业的预期情景。“由于快速更换系统和较短的安装时间,系统上的产品更换没有问题且经济上合理:在加速期间,FPP系统的容量可用于多个组件。随着数量的增加,机器公园得到扩展,系统变得更加专注。优势:流程保持不变 - 无需新产品开发,也无需重新认证零件。“

“由于FPP和AFP工艺都用于航空航天工业,FPP和AFP的层压板规划是否可以在我们的CAE软件ARTIST STUDIO中结合使用的问题,自然而然地在开发过程中出现。明确的答案:是的,它可以是合并后,“Cevotec执行副总裁Neven Majic博士补充道。

因此,FPP专家目前正在通过AFP工艺中使用的无端纤维带的层压设计相关功能扩展ARTIST STUDIO。新模块TAPE ARTIST与ARTIST STUDIO无缝集成,还将使用MOTION ARTIST进行机器数据生成和过程模拟。TAPE ARTIST还可以与PATCH ARTIST结合使用到一个联合模块,使工程师能够设计基于AFP和FPP技术的集成层压板。

原文如下: Cevotec expands application range by multi-material layup for sandwich structures

Fiber Patch Placement (FPP) has become the preferred technology for the automated production of complex fiber composite components. The additive manufacturing of components with suitably-sized patches is used especially in the aerospace and automotive industries, for medical devices and sports equipment. In close cooperation with leading manufacturers of components for the aerospace industry, Cevotec further develops the entire patch placement process according to the requirements of the industry.

Cevotec’s FPP specialists are particularly interested in complex sandwich components with their sophisticated material mix, such as adhesive films, glass fiber and carbon fiber layers. These different materials are used to improve the adhesion and processability of carbon fiber material with the often-used aluminum honeycomb sandwich cores.

"The SAMBA Multi production systems, which we are currently developing, enables the automated lay-up of this special multi-material mix in one single system," reports Felix Michl, Cevotec's CTO.

In addition to glass fiber fleeces, metal structures and wood cores, also honeycomb cores, solid foams and additional materials have already enjoyed load-adjusted fiber patch reinforcements. Depending on process requirements, this can be done in-line or parallel to line production to optimize cycle times.

SAMBA Multi has parallel feeding units for different materials that are processed in one production system and placed precisely on 3D sandwich cores or preforming tools. By mounting the FPP unit on a linear axis, the concept also enables the production of particularly long and wide components in aerospace applications. Adapted to specific component sizes, we also scaled the patch grippers to DIN-A5 and DIN-A4 size to meet the requirements of common aircraft components. An integrated gripper station enables the exchange of grippers during the process.

"The automated multi-material lay-up of complex sandwich components has an extremely positive effect on process times and thus the production volume," explains Thorsten Groene, Managing Director of Cevotec: "The fiber deposition with controlled pressure and heat enables skipping intermediate compactions and thus reduces process times significantly.” In addition, Groene continues, FPP sustainably reduces recurring production costs in many applications. "Material savings of 20% - 50% play a major role, of course, but automation with FPP often enables further optimization of the overall process.”

Another advantage of SAMBA Multi is the high scalability of the production process. "One and the same process works both for a few hundred and several thousand units per year," explains Michl. These are expected scenarios in the up-and-coming “flying car” industry, for example. " Thanks to the quick-change system and short set-up times, a product change on the system is no problem and economically reasonable: During ramp-up, an FPP system’s capacity can be used for several components. With increasing quantities, the machine park is expanded and the systems become more dedicated. The advantage: the process remains the same – no new product development and no re-qualification of parts are necessary."

"Since both FPP and AFP processes are used in the aerospace industry, the question whether laminate planning for FPP and AFP can be combined in our CAE software ARTIST STUDIO, naturally arose in the course of development. The clear answer: yes, it can be combined," adds Dr. Neven Majic, EVP at Cevotec.

Therefore, the FPP specialists are currently extending ARTIST STUDIO by the relevant features for laminate design with endless fiber tapes as used in AFP processes. Seamlessly integrated into ARTIST STUDIO, the new module TAPE ARTIST will also use MOTION ARTIST for machine data generation and process simulation. TAPE ARTIST can also be combined with PATCH ARTIST to one joint module, enabling engineers to design integrated laminates based on AFP and FPP technology.