科思创引入Maezio作为热塑性复合材料的品牌名称

通过引入Maezio作为品牌,科思创正在推动其连续纤维增强热塑性复合材料(CFRTP)的开发和营销。

这些创新材料旨在满足对强光材料的需求,这些材料有助于节约资源和提高能源效率。从移动和电子行业到消费品和医疗产品,OEM和零件供应商可以从先进复合材料的高性能功能中受益,同时享受Maezio提供的经济高效且可扩展的制造解决方案。

“该品牌为我们提供了明确而强大的身份,以进一步扩大我们在热塑性复合材料方面的专业知识,”CFRTP的联合席执行官David Hartmann说道,他是CFRTP复合材料的两位联合席执行官之一,与迈克尔施密特博士一起。

“我们相信,通过提供轻质结构,特定强度和表面处理的组合,新型品牌可以真正为各行业的下一代产品带来价值。”

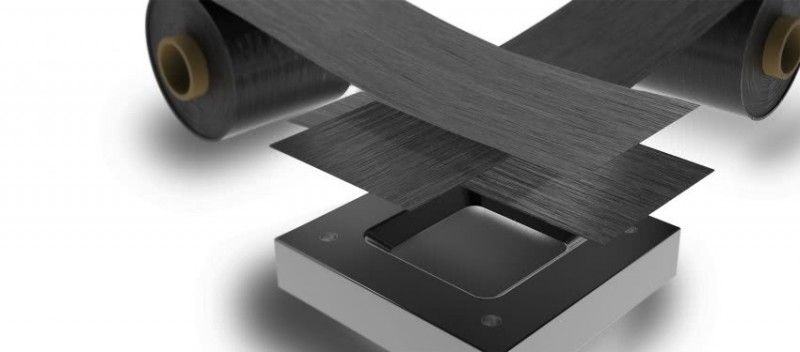

明天的材料复合材料基于浸渍有聚碳酸酯,热塑性聚氨酯(TPU)或其他热塑性树脂的连续碳纤维或玻璃纤维。通过这些组件,科思创在德国南部Markt Bibart的生产现场生产单向增强带和板材,供客户进一步加工。这些组件坚固,轻盈,美观,可以组合成无限数量的产品,为设计师提供创造性机会。

到目前为止,先进复合材料的进一步传播受到缺乏成本效益和可扩展制造工艺的阻碍。除此之外,很难将它们整合到大批量产品中。所有这些都将随着Maezio复合材料而改变。

适合大批量生产

它们可以使用现有的热成型工具进行热成型,生产率高,循环时间短。当制造规模每年可以达到数百万个零件时,这一点至关重要。其他生产技术,如混合注塑,自动UD带铺设和自动纤维放置,可以轻松集成。

作为热塑性复合材料,Maezio产品可以在其使用寿命结束时进行回收,使其成为“可扩展和可持续复合材料解决方案在为行业提供推动边界的材料工具方面的完美典范”,Michael Schmidt说。

许多行业对Maezio的浓厚兴趣正在吸引人们对电气和电子行业,汽车行业,家用电器制造商和家具生产商,医疗技术,体育用品制造商,鞋类生产商和箱包行业等不同领域的兴趣。

海尔以Casarte品牌推出了先进的空调,利用Maezio作为产品的主要外壳。在鞋类领域,复合材料帮助运动服创业公司Bmai开发出更轻,更强的马拉松鞋,这对运动员和休闲运动员都有好处。

原文如下:

原文如下:

Covestro is pushing ahead with developing and marketing its continuous fiber-reinforced thermoplastic composites (CFRTP) by introducing Maezio as brand name.

Covestro introduces brand name for thermoplastic composites

These innovative materials are set to tap into the growing demand worldwide for strong and light materials that contribute to resource conservation and energy efficiency. From mobility and electronics industries to consumer goods and medical products, OEMs and part suppliers can benefit from the high performance capabilities of advanced composites while enjoying cost-effective and scalable manufacturing solutions offered by Maezio.

“The brand gives us a clear and strong identity to further expand our expertise in thermoplastic composites,” says David Hartmann, Co-CEO of CFRTP, one of the two Co-CEOs for CFRTP composites alongside Dr. Michael Schmidt.

“We believe the new brand can truly bring value to next-generation products across industries by delivering a combination of lightweight construction, specific strengths and finishes at a scale unreachable by advanced materials today.”

Material of tomorrow

The composite material is based on continuous carbon or glass fibers impregnated with polycarbonate, thermoplastic polyurethane (TPU) or other thermoplastic resins. From these components, Covestro produces uni-directional reinforced tapes and sheets at the production site in Markt Bibart in south Germany for further processing by customers. Being strong, light, and aesthetic, these components can be combined into an unlimited number of products, giving designers creative opportunities.

So far a further propagation of advanced composites was hampered by lack of cost-effective and scalable manufacturing processes. Besides that it is difficult to integrate them into high-volume products. All of this is about to change with Maezio composites.

Suitable for mass production

They can be thermoformed with existing thermoforming tools at high yield rates and low cycle times. This is vital when manufacturing scales can be in the range of millions of parts per year. Other production technologies such as hybrid injection molding, automated UD tape laying and automated fiber placement can be easily integrated.

As thermoplastic composites, Maezio products can be recycled at the end of their useful life, making them “a perfect example of what scalable and sustainable composite solutions look like in giving industries the material tools to push boundaries,” says Michael Schmidt.

Strong interest from many sectors

Maezio is attracting interest in such diverse segments as the electrical and electronics industry, the automotive business, household appliance manufacturers and furniture producers, medical technology, sports goods manufacturers, shoe producers and the luggage industry.

Haier has launched a state-of-the-art air conditioner under its Casarte brand, which utilizes Maezio for the main housing of the product. In the world of footwear, the composites have helped Chinese athletic wear startup Bmai to develop even lighter and stronger marathon shoes which benefit athletes and leisure runners alike.