3D打印零件和新材料有助于劳斯莱斯发动机测试成功

该技术演示引擎正在证明技术和一个新的核心劳斯莱斯超级风扇发动机设计,将在2025年推出。

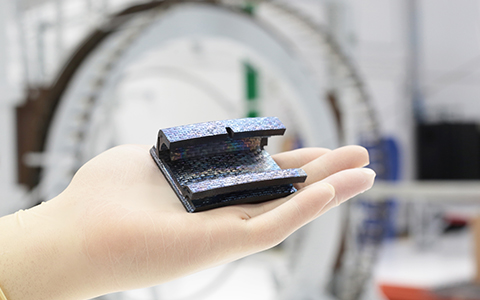

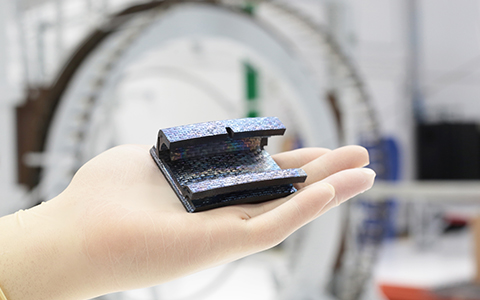

Advance3,包括约20,000个部件,已达到100多个小时的测试。初步结果显示,由印刷技术制造的零件,即添加剂层制造(通常称为3D打印)和陶瓷基复合材料制成的零件具有良好的性能。

ALM允许工程师为零件创造新的设计,并使这些部件更快地被制造和重新设计。CMCs在高温下持续时间更长,比金属替代品更轻。

工程师们从去年11月开始的测试中下载了数以百万计的数据点,并在7月份实现了发动机的满负荷运转。Advance3在提供智能引擎、劳斯莱斯对未来的愿景方面发挥着重要作用,因为它建立在先进技术和数字能力的基础上,为客户提供了重要的利益。

民用航空航天演示项目总工程师艾什·欧文(Ash Owen)表示:“迄今为止,测试是完全无缝的,当你意识到这是一个包含一系列新技术和全新核心架构的引擎时,这是一项杰出的成就。我们现在已经完成了测试和分析结果的阶段。我们喜欢从CMC和ALM部件性能中看到的。“

CMC组件能够承受较高的工作温度,所需的冷却空气要少得多,同时还能显著减轻重量,所有这些都有助于提高效率。

ALM允许具有多个部件的更复杂的发动机元件在更少的部件中制造,甚至作为一个完整的部件来制造,从而提高了准备时间,并允许在开发阶段快速、轻松地重新设计组件。劳斯莱斯在这一过程中一直处于创新的前沿,在2015年测试的特伦特XWB-97发动机内驾驶了大型3D打印的航空航天结构。ALM还提高了生产效率,降低了组件的重量,同时提供了制造设计和形状的能力,而这些设计和形状是传统方法不可能实现的。

Advance3演示器正在测试一种新的发动机核心,它将提供佳的燃油效率和低排放。罗尔斯-罗伊斯未来的技术战略的一个关键要素是为超级风扇发动机设计开发先进核心,该核心将于2025年推出,与代特伦特发动机相比,它将使燃油效率提高25%。

在演示器上,新的核心运行在Trent XWB风扇系统和Trent 1000低压涡轮之间,其压缩机系统有助于提供高达70:1的超风扇总压力比。

Advance3演示方案是由航空航天技术研究所(ATI)与Innovate UK和CleanSky 2联合资助的。

原文如下:

原文如下:

The technology demonstrator engine is proving both technology and a new core for Rolls-Royce UltraFan engine design which will be available from 2025.

3D printed parts and new materials help Rolls-Royce to engine test success

Advance3, incorporating around 20,000 parts in total, has achieved more than 100 hours on test. Initial results are showing good performance from parts made by a printing technique known as additive layer manufacturing (more commonly known as 3D printing) and also made from ceramic matrix composites.

ALM allows engineers to create new designs for parts, and for those parts to be made and redesigned more quickly. CMCs last longer in high temperatures and are lighter than metal alternatives.

Engineers have downloaded millions of data points from the tests, which began last November and saw the engine achieve full power in July. Advance3 plays an important part in delivering the IntelligentEngine, Rolls-Royce’s vision for the future, as it builds on pioneering technology and digital capabilities to deliver important benefits for customers.

Ash Owen, Rolls-Royce, Chief Engineer, Civil Aerospace Demonstrator Programmes, said: “Testing so far has been completely seamless, which is an outstanding achievement when you realise that this is an engine incorporating a range of new technologies as well as a brand new core architecture. We have completed our first phase of testing and analysing the results right now. We like what we see from the CMC and ALM parts performance. ”

CMC components are able to withstand higher operating temperatures, and require much less cooling air, while delivering a significant weight reduction, all contributing to improved efficiency.

ALM allows more complex engine elements with multiple pieces to be manufactured in fewer parts or even as a single complete part, improving lead times and allowing components to be redesigned quickly and easily during the development phase. Rolls-Royce has been at the forefront of innovation with this process, flying a large 3-D printed aerospace structure within the Trent XWB-97 engine that was tested in 2015. ALM also increases production efficiency and reduces component weight while providing the ability to manufacture designs and shapes that would not be possible using conventional methods.

The Advance3 demonstrator is testing a new engine core that will deliver optimum fuel efficiency and low emissions. It is a key element in Rolls-Royce’s future technology strategy to develop the Advance core for the UltraFan engine design that will be available from 2025 and will offer a 25 per cent improvement in fuel efficiency compared with a first generation Trent engine.

On the demonstrator, the new core operates between a Trent XWB fan system and a Trent 1000 low pressure turbine, and its compressor system helps to deliver an UltraFan overall pressure ratio of up to 70:1.

The Advance3 demonstrator programme is co-funded through the Aerospace Technology Institute (ATI) in association with Innovate UK and Clean Sky 2.