NASA和Nanocomp开发碳纳米管复合材料

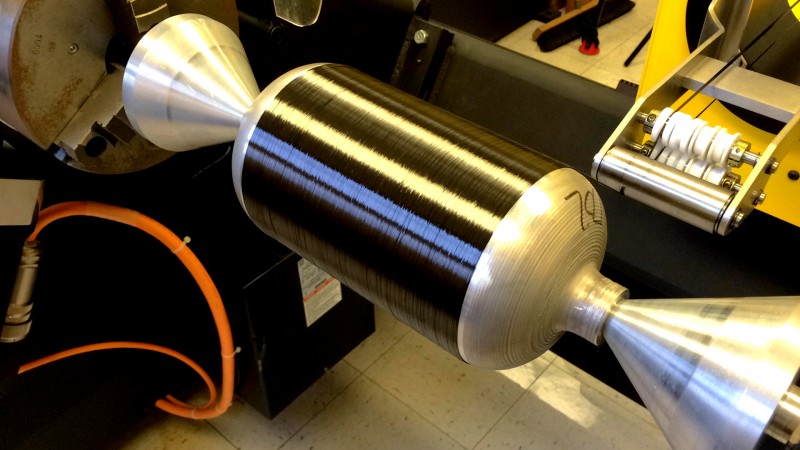

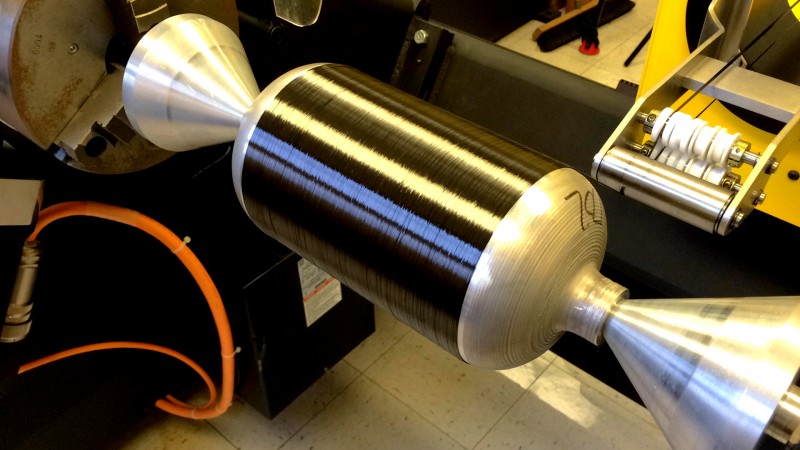

美国宇航局已与Huntsman公司Nanocomp签订合同,继续开发他们的高强度碳基材料,名为Miralon。

Miralon由相互连接、长格式的纳米管束组成,主要生产薄板、纱线、胶带和分散产品.它非常轻,坚固,具有延展性和导电性能,并使热传输跨越几种材料格式和应用。

掌握纳米级物质控制的复杂性,是应用纳米技术造福工业过程的革命性探索的一部分。这项技术的一个关键要素是碳纳米管的使用。

碳纳米管是一种小的空心管,直径为0.7~50纳米,长度一般为几十微米。而超小的碳纳米管提供了大量的特性。

例如,材料可以表现出优异的强度,但仍然非常轻。想想看,钢的强度是200倍,弹性是5倍。为了更好地测量,它们提供了高效的导电和热导率.

原文如下: NASA has contracted with Nanocomp, a Huntsman company, for the continued development of their high-strength, carbon-based material called Miralon.

NASA and Nanocomp to develop carbon nanotube composites

Composed of interconnected, long-format nanotube bundles, Miralon is produced as sheets, yarn, tape and dispersed products. It is extremely lightweight, strong, ductile, and electrically conductive, and enables thermal transport across several material formats and applications.

Mastering the intricacies of controlling matter at the nanoscale level is part of a revolutionary quest to apply nanotechnology to benefit industrial processes. A key element of that technology is the use of carbon nanotubes.

Carbon nanotubes are small hollow tubes with diameters of 0.7 to 50 nanometers and lengths generally in the tens of microns. While ultra-small, carbon nanotubes offer big-time attributes.

For instance, materials can be manufactured that exhibit superior strength but are still extremely lightweight. Think in terms of 200 times the strength and five times the elasticity of steel. For good measure, add in that they offer highly-efficient electrical and thermal conductivity.