用于PlyMatch复合材料制造的AR技术

英国复合材料设计和制造解决方案专家Anaglyph将于3月份在JEC World 展示新版本的手工铺层铺设技术PlyMatch。

原文如下:

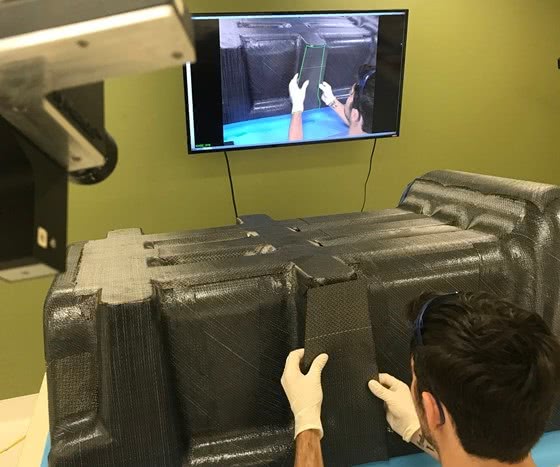

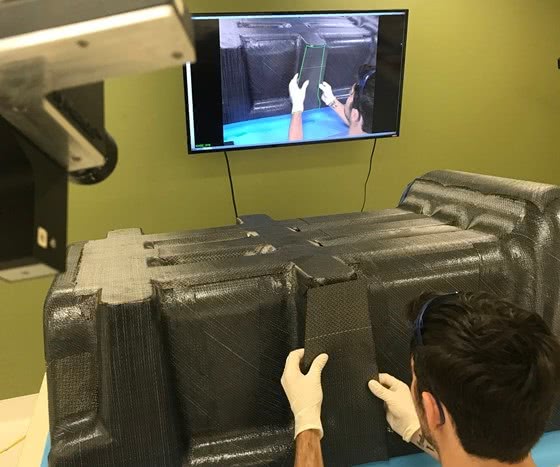

PlyMatch使用增强现实技术在显示器上显示实际和目标层轮廓和纤维方向细节的实时组合图像,以便操作员可以匹配这两者。它用于复合材料零件的手工铺层制造中的层的精确放置,以及用于自动化方法的监控和验证。它在复杂的几何形状,高曲率或封闭空间的情况下特别有用。

据该公司报道,PlyMatch目前在航空航天,汽车,自行车和运输行业的制造商中使用。

“ Laminate Tools是一个独立的Windows应用程序,与大多数行业标准接口。它解决了整个设计 - 分析 - 检查 - 制造小组的结构设计过程,但侧重于复合材料的特点,“该公司解释说。“它补充了您现有的CAD系统和/或FEA环境。Laminate Tools具有Solidworks,Rhino,Nastran,HyperMesh,Ansys和Abaqus的原生界面。它有助于优化和制造精确的设计,节省宝贵的团队时间。“

CoDA(复合构件设计分析)用于具有板,梁,接头,法兰或层压板几何形状的初步分析子构件。

基于经典层压理论,LAP(层压分析程序)用于分析受到面内载荷和力矩的任何类型的复合层压板。除了厚度之外,平板层压板没有固定的尺寸,因此分析可以应用于已知载荷和变形的任何复合部件。

20多年来,Anaglyph一直为复合材料设计和制造提供解决方案。其软件正在30多个使用。 原文如下:

Anaglyph, the UK composites design and manufacturing solutions specialist, will demonstrate the latest version of its hand-layup ply placement technology PlyMatch at JEC World, in March.

PlyMatch uses augmented reality to show the live combined images of actual and target ply outlines and fibre orientation details on a monitor, so that the two can be matched by the operator. It is used for the accurate placement of plies in hand lay-up manufacture of composite parts, as well as for monitoring and validation of automated methods. It is particularly useful in case of complex geometries, with high curvature or enclosed spaces.

PlyMatch uses augmented reality to show the live combined images of actual and target ply outlines and fibre orientation details on a monitor. ? Anaglyph

PlyMatch is used by manufacturers in aerospace, automotive, bicycle and transport sectors at this stage, the company reports.

“Laminate Tools is a stand-alone Windows application, interfacing with most industry standards. It addresses the entire Design-Analysis-Check-Manufacture group process of structural design but focusing on the composite material features,” the company explains. “It complements your existing CAD systems and/or FEA environments. Laminate Tools has native interfaces to Solidworks, Rhino, Nastran, HyperMesh, Ansys and Abaqus. It helps optimise and manufacture exactly what is being designed and saves valuable team time.”

CoDA (Composite Component Design Analysis) is used for preliminary analysis sub-components with Plate, Beam, Joint, Flange or Laminate geometries.

based on Classical Laminate Theory, LAP (Laminate Analysis Program) is used to analyse any type of composite laminate subjected to in-plane loads and moments. The flat laminate is no fixed size, apart from its thickness, so that the analysis can be applied to any composite component wher loadings and deformations are known.

Anaglyph has been offering solutions for composites design and manufacturing for over 20 years. Its software is being used in more than 30 countries worldwide.