复合材料部件完成碳纤维电动自行车的设计和制造

Ryuger自行车与复合材料部件公司签订合同,设计和制造一款以舒适性,巡航和距离为主要目标的新型电动自行车。

原文如下:

11月,建筑的道路测试阶段结束了2年的设计,测试,建造和装配。该项目现在正在运行,以期明年生产。

这是复合材料组件次构建的自行车,但是一开始我们的客户Ryuger自行车有一些关键输入,项目运行平稳,终结果是一辆完全解决的电动自行车,大距离超过160公里低费用。

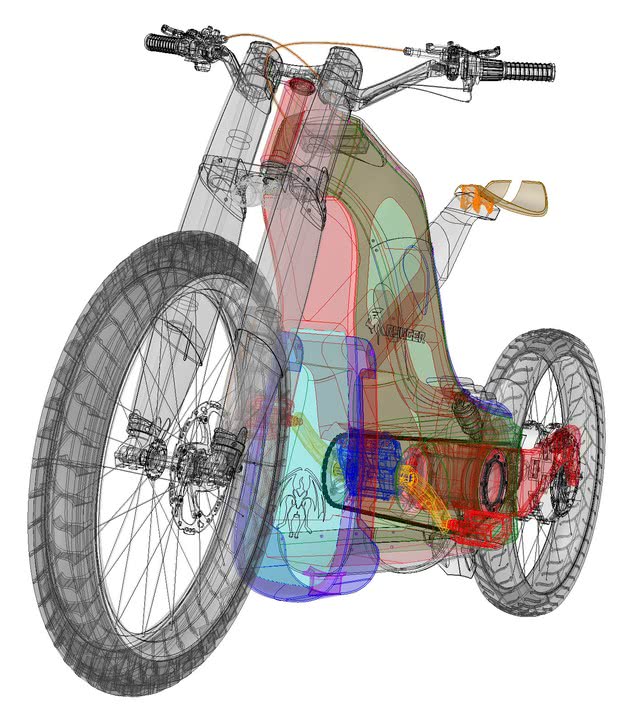

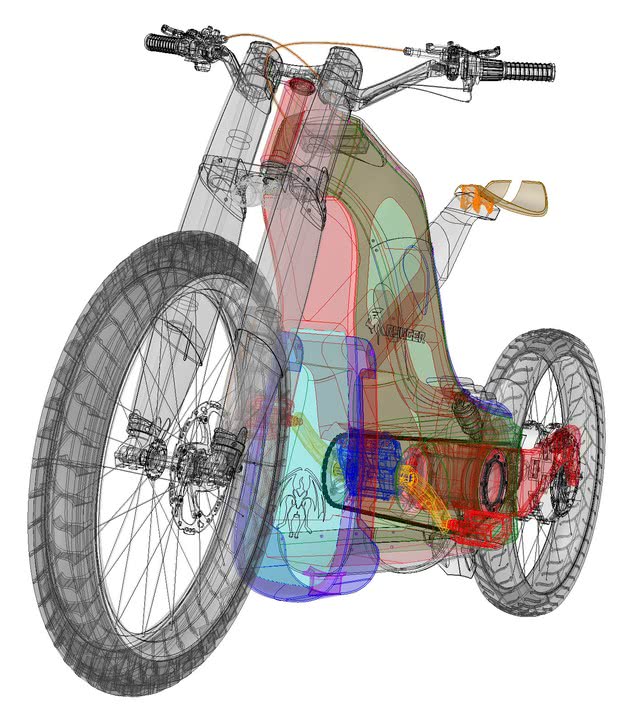

广泛使用Solidworks,Rhino 3D和我们的内部3D打印和CNC功能有助于使构建过程成为简单装配的问题,而不是修改和返工的过程。

自行车采用了大量的碳纤维,几乎90%的定制零件设计和制造,以满足舒适性,范围和易用性以及完全享受的特定目的。

Ryuger bikes contracted Composite Components to design and build a new electric bicycle with comfort, cruise and distance as key objectives.

Composite Components complete design and build of carbon fibre electric bicycle

November saw the road testing phase of the build completed ending 2 years of design, test, build and assembly. The project now runs with a view to production next year.

This is the first bicycle Composite Components have built, but with a few key inputs from our client Ryuger bikes at the beginning, the project ran smoothly and the end result is a fully resolved electric bicycle with a max range of over 160 kilometers from a 40 min charge.

Making extensive use of Solidworks, Rhino 3D and our in house 3D printing & CNC capabilities assisted to make the build process a matter of simple assembly, rather than a process of modifications and rework.

The bicycle is extensively carbon fibre with almost 90% bespoke parts designed and built for the specific purpose of comfort, range and ease of service and total enjoyment.