后固化碳纤维复合材料的表面加热

Ceramicx介绍了一种利用各种红外发射器在大约15秒内将固化后碳纤维复合材料的表面加热到235°C的工艺。

查询

一家一级航空航天制造商要求提交一份报告,详细说明各种陶瓷红外发射器对一种独特的固化后碳纤维复合材料表面进行加热的能力。目标是使复合材料的表面在大约15秒内达到235°C。复合材料中的环氧树脂是热固性塑料,因此,如果温度过高,就会永久燃烧和变形。

解决方法

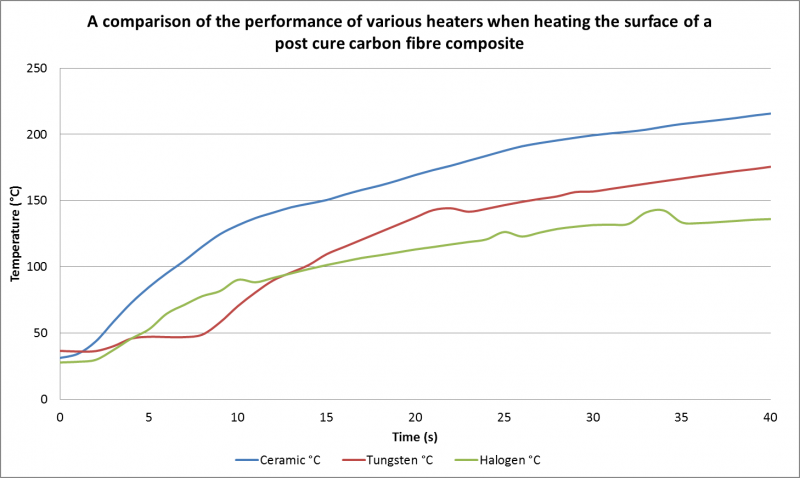

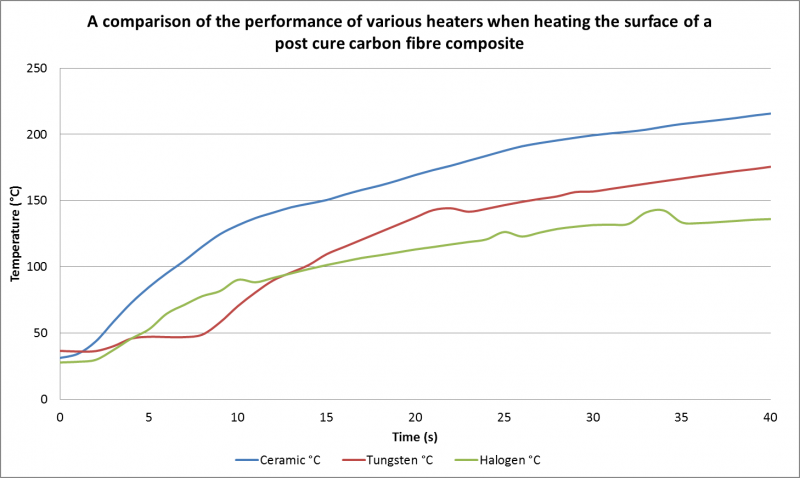

与C平方公里试验室内的大多数材料测试一样,初步测试的目的是确定哪种类型的发射器(长波、中波或短波)适合这项工作。在目标距离为100 mm的固定元件上,长波陶瓷元件的性能优于中波钨和短波卤素管。

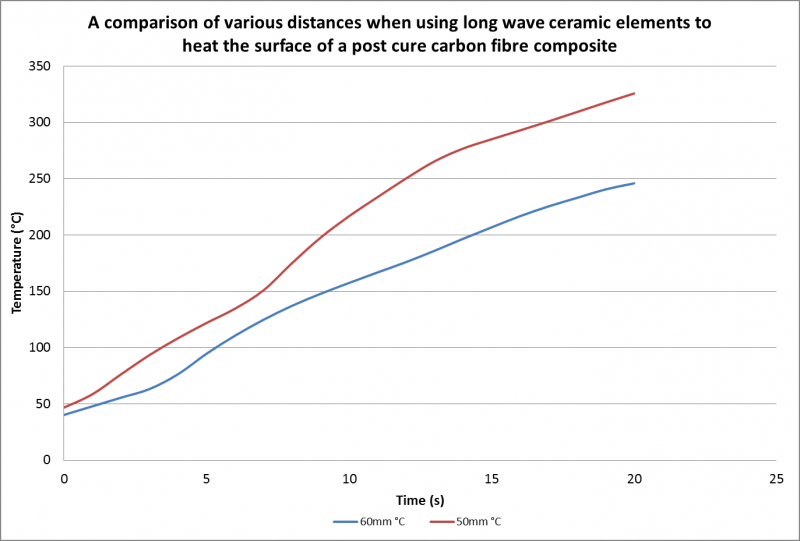

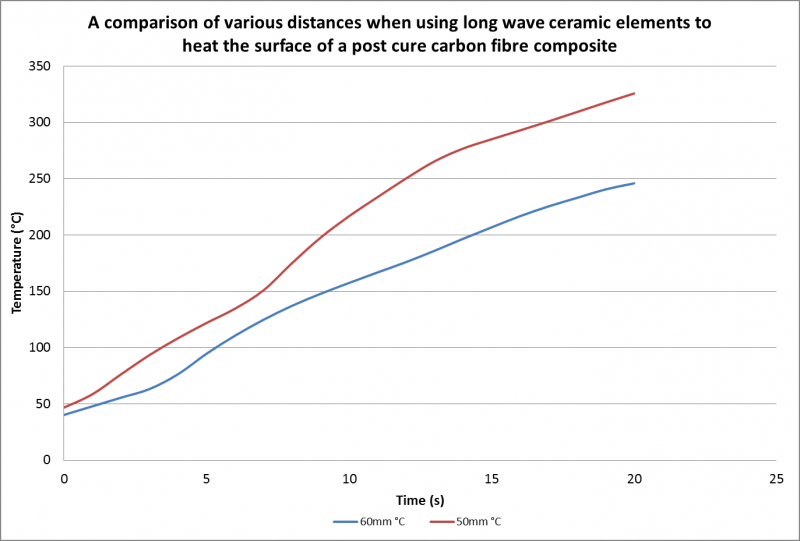

结果表明,加热元件布置为6x800W黑色SFEH元件,排列在3x2阵列中。根据这一决定,为了达到温度指标,需要缩小元素与目标材料之间的距离。由于100毫米显然太大的一段距离,这是减少到60毫米,并反过来50毫米,并注意到结果。

结果

对于所涉加热元件的布置(瓦特密度为44.8千克/米),复合材料表面的距离为50毫米,可在大约11秒内达到235℃的规定温度,而且在15秒的时限内很好。

表面吸收热辐射并将其转化为热的能力因材料而异,特别是在复合材料之间。为了大限度地提高效率,在开发一个项目之前,确定适合某一特定材料的合适的发射器是至关重要的。

原文如下: Ceramicx introduces a process to heat the surface of a post cure carbon fibre composite to 235°C in approximately 15 seconds usind various infrared emitters.

Surface heating of a post cure carbon fibre composite

Enquiry

A tier 1 aerospace manufacturer requested a report detailing the ability of various Ceramicx infrared emitters to heat the surface of a unique post cure carbon fibre composite. The target was to bring the top surface of the composite to 235°C in approximately 15 seconds. The epoxy resin within the composite is a thermoset plastic, therefore, should the temperature get too high it would permanently burn and deform.

Solution

As with most material tests within the C?I? test room, the initial tests were to find out which type of emitter (long, medium or short wave) was most suited to the job. At a fixed element to target distance of 100mm, it was found that the long wave ceramic elements outperformed the medium wave tungsten and the short wave halogen tubes.

A comparison of the performance of various heaters when heating the surface of a post cure carbon fibre composite

based on the results, the heating element arrangement used was 6 x 800W black SFEH elements arranged in a 3 x 2 array. Following this decision, the distance between the elements and the target material would need to be reduced in order to reach the temperature target. As 100mm was clearly too large of a distance, this was reduced to 60mm, and in turn 50mm, and the results were noted.

A comparison of various distances when using long wave ceramic elements to heat the surface of a post cure carbon fibre composite

Result

For the heating element arrangement in question (watt density of 44.8 kN/m?), a distance of 50mm was suitable for the surface of the composite to reach the required temperature of 235°C in approximately 11 seconds, well within the time restriction of 15 seconds.

The ability of a surface to absorb thermal radiation and covert it to heat varies between materials, particularly between composites. To maximise efficiency, it is crucial that the most suitable emitter for a specific material is determined before developing a project.