EXEL复合材料公司与Ziebel公司配合开发复合材料在油井传感器上的应用

提高采收率

稳健的制造过程

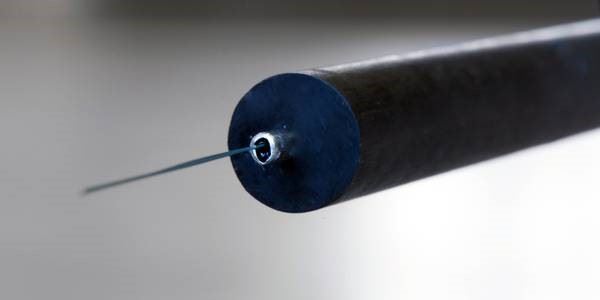

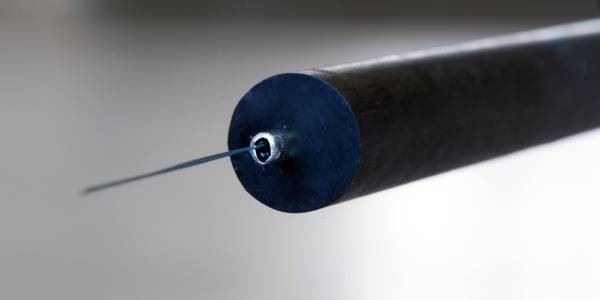

由于碳纤维和光纤的高成本,加工风险非常高,”DSC的技术和业务发展总监DavidLewis解释道。因此,我们开展了广泛的工作,开发出一种非常健壮和万无一失的拉挤工艺,并建立了特殊的工艺控制,以确保不出现故障。由于碳纤维和光纤的高成本,加工风险非常高,”DSC的技术和业务发展总监DavidLewis解释道。因此,我们开展了广泛的工作,开发出一种非常健壮和万无一失的拉挤工艺,并建立了特殊的工艺控制,以确保不出现故障。“

未来发展

我们对DSC的合作伙伴有很大的信任和信心,这将使我们能够在充满敌意的油井和气井井下环境中继续推进碳复合材料的边界。齐贝尔的技术副总裁尼尔·加德纳(NeilGardner)说:“我们的下一代Z-Rod将把我们的工作温度提高到华氏350度(177摄氏度),为我们的服务开辟更多的油井。我们对DSC的合作伙伴有很大的信任和信心,这将使我们能够在充满敌意的油井和气井井下环境中继续推进碳复合材料的边界。齐贝尔的技术副总裁尼尔·加德纳(NeilGardner)说:“我们的下一代Z-Rod将把我们的工作温度提高到华氏350度(177摄氏度),为我们的服务开辟更多的油井。”

我们祝贺Ziebel成功地引入了他们创新的油井干预系统,我们期待着与他们合作,以进一步扩大其应用,”Kari Loukola说,SVP Exel美洲复合材料和DSC总裁。“这个项目清楚地展示了DSC给Exel集团带来的碳拉挤能力,通过我们的合并、扩展,我们预计在石油和天然气部门以及风能和航空航天等其他关键市场将有重大机遇。我们祝贺Ziebel成功地引入了他们创新的油井干预系统,我们期待着与他们合作,以进一步扩大其应用,”Kari Loukola说,SVP Exel美洲复合材料和DSC总裁。“这个项目清楚地展示了DSC给Exel集团带来的碳拉挤能力,通过我们的合并、扩展,我们预计在石油和天然气部门以及风能和航空航天等其他关键市场将有重大机遇。”

Improving oil recovery factors

A robust manufacturing process

nal process controls are in place to ensure that there are no failures.""Because of the high cost of both the carbon fiber and the fiber optics, the process risk is very high," David Lewis, DSC's Director of Technology & Business Development explains. "We've therefore performed extensive work to develop a pultrusion process that is extremely robust and foolproof, and exceptional process controls are in place to ensure that there are no failures."

Future developments

nfidence in our partners at DSC that will enable us to continue pushing the boundaries for carbon composites in the hostile downhole environments of oil and gas wells. Our next generation of Z-Rod will take us to operating temperatures of 350 degrees F (177 degrees C), opening up additional wells for our services," Neil Gardner, Ziebel's Vice President of Technology says."We have a great deal of trust and confidence in our partners at DSC that will enable us to continue pushing the boundaries for carbon composites in the hostile downhole environments of oil and gas wells. Our next generation of Z-Rod will take us to operating temperatures of 350 degrees F (177 degrees C), opening up additional wells for our services," Neil Gardner, Ziebel's Vice President of Technology says.

ngratulate Ziebel on the successful introduction of their innovative well intervention system and we look forward to collaborating with them to further extend its application," states Kari Loukola, SVP Exel Composites Americas and President of DSC. "This project is a clear demonstration of the capabilities in carbon pultrusion that DSC brings to the Exel group and with our combined, expanded offering we anticipate significant opportunities in the oil and gas sector and other key markets such as wind energy and aerospace "We congratulate Ziebel on the successful introduction of their innovative well intervention system and we look forward to collaborating with them to further extend its application," states Kari Loukola, SVP Exel Composites Americas and President of DSC. "This project is a clear demonstration of the capabilities in carbon pultrusion that DSC brings to the Exel group and with our combined, expanded offering we anticipate significant opportunities in the oil and gas sector and other key markets such as wind energy and aerospace."